Engineering Your Road to Success

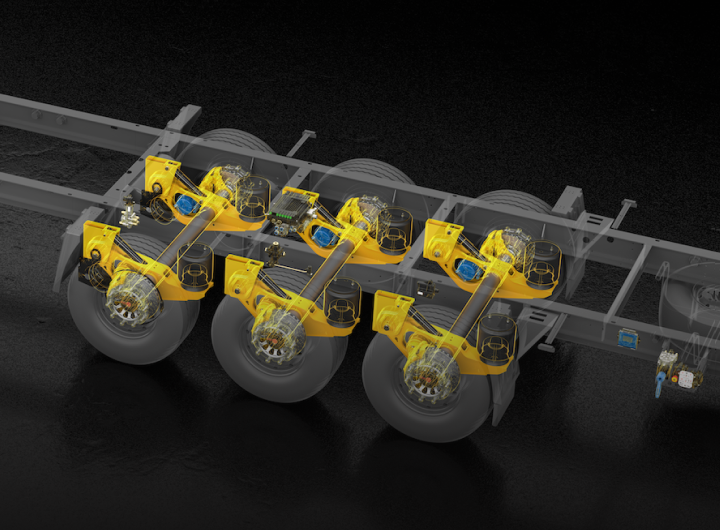

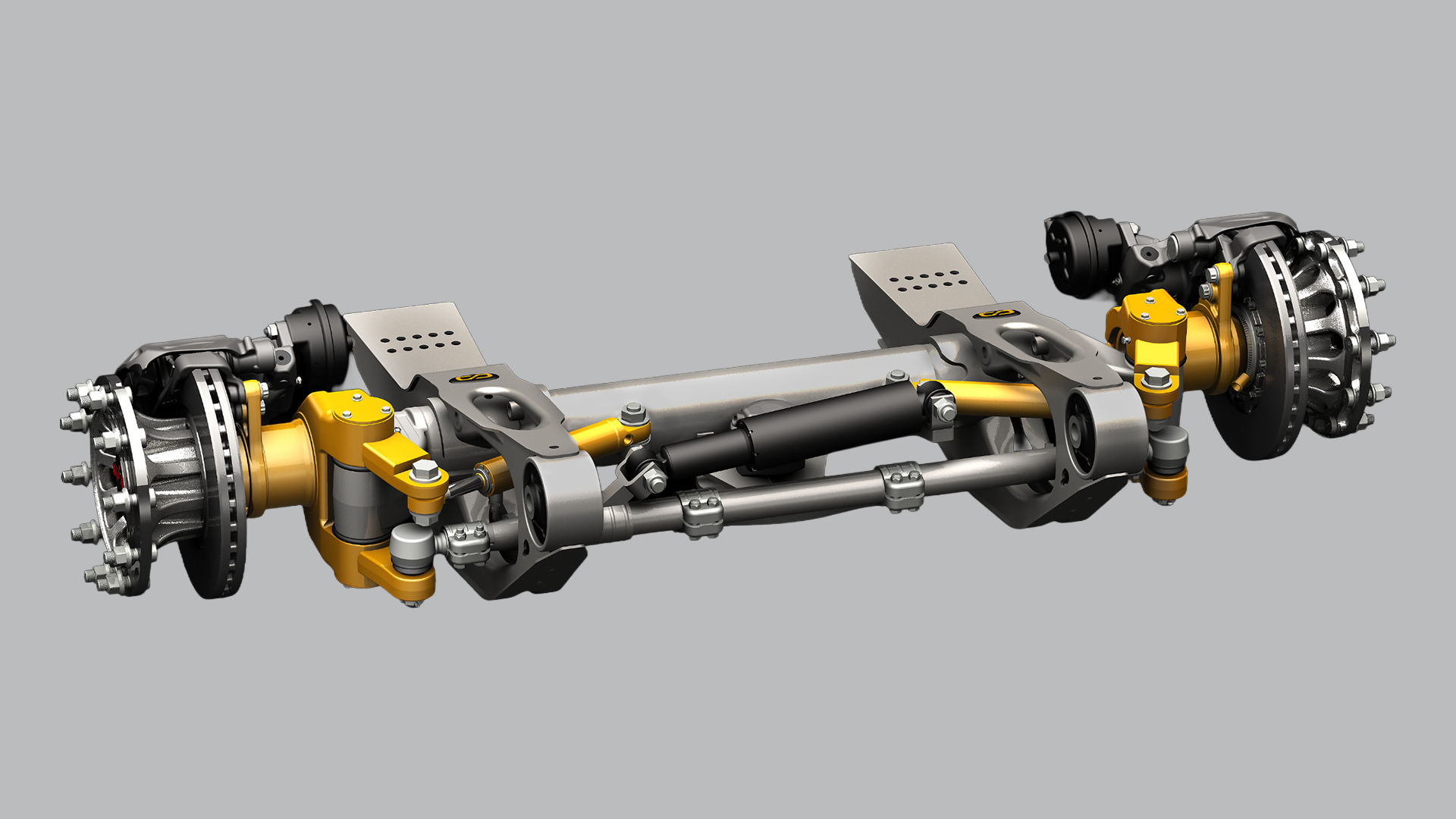

The SAF-HOLLAND Group is one of the leading international manufacturers of chassis-related assemblies and components for trailers, trucks and buses. The product range includes axle and suspension systems, fifth wheels, coupling systems, kingpins and landing legs. These products are known worldwide under the brands SAF, HOLLAND, HALDEX, KLL, NEWAY, TRAILERMASTER, V.ORLANDI and YORK.

News

Always stay up to date.

Here you can read news about products, current topics and news events as well as events of the SAF-HOLLAND Group.

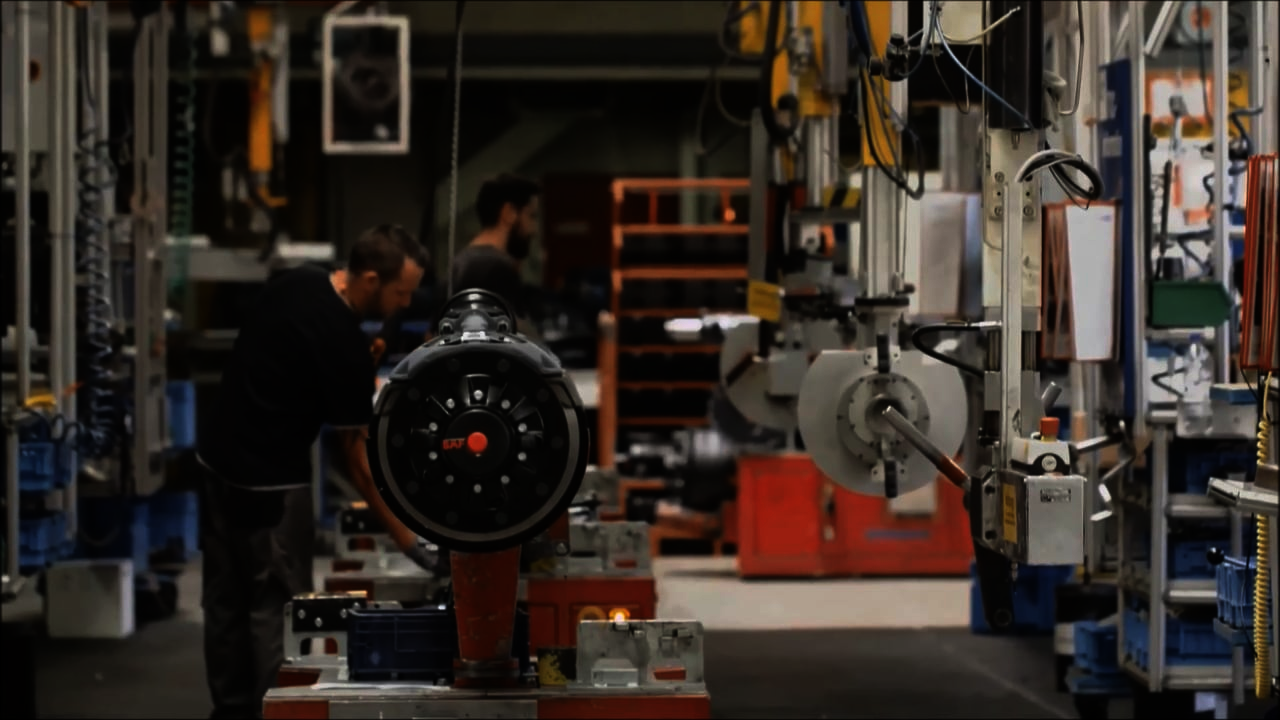

Production Insight

Over 300,000 axles and chassis systems leave the European production sites every year.

To ensure that each individual suspension system meets the high quality and safety standards of our customers requires many years of expertise in the field of axles and suspension systems, a high degree of automated production processes and sophisticated logistics.

This is the only way we can deliver consistent quality, because trucking companies and drivers around the world rely on SAF axles every day.

Engineering Your Road to Success.

Events

Meet us in person!

Exchange ideas with us at one of the many trade fairs and events and experience the SAF-HOLLAND product world in person. We look forward to welcoming you at one of the following events: