Recuperation Axle SAF TRAKr - Applied Future

The use of electrified trailer axles is becoming increasingly important for low-emission transport.

Regulatory frameworks such as VECTO (Vehicle Energy Consumption Calculation) are major drivers of innovation in e technology. In addition, more than 50 zero emission zones are expected to be introduced across Europe in the near future. Stricter noise protection regulations are encouraging manufacturers to develop significantly quieter vehicles. To meet planned global climate targets, CO₂ emissions must be reduced by up to 95 percent by 2030.

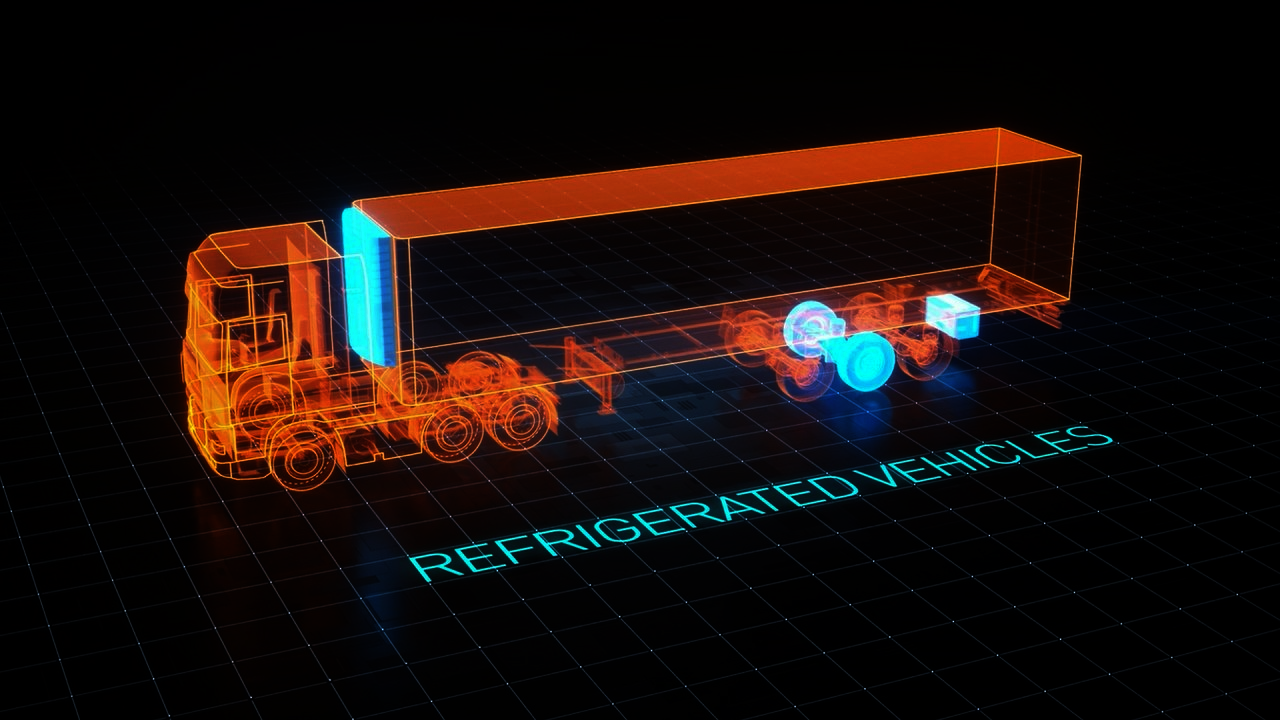

Application of SAF TRAKr

The SAF TRAKr trailer axle uses recuperation to recover energy to be used in

- Coolers / Reefers

- Food Tankers / Silos

- Walking Floor Trailers

- Liftgates

- Transportable E-Forklifts

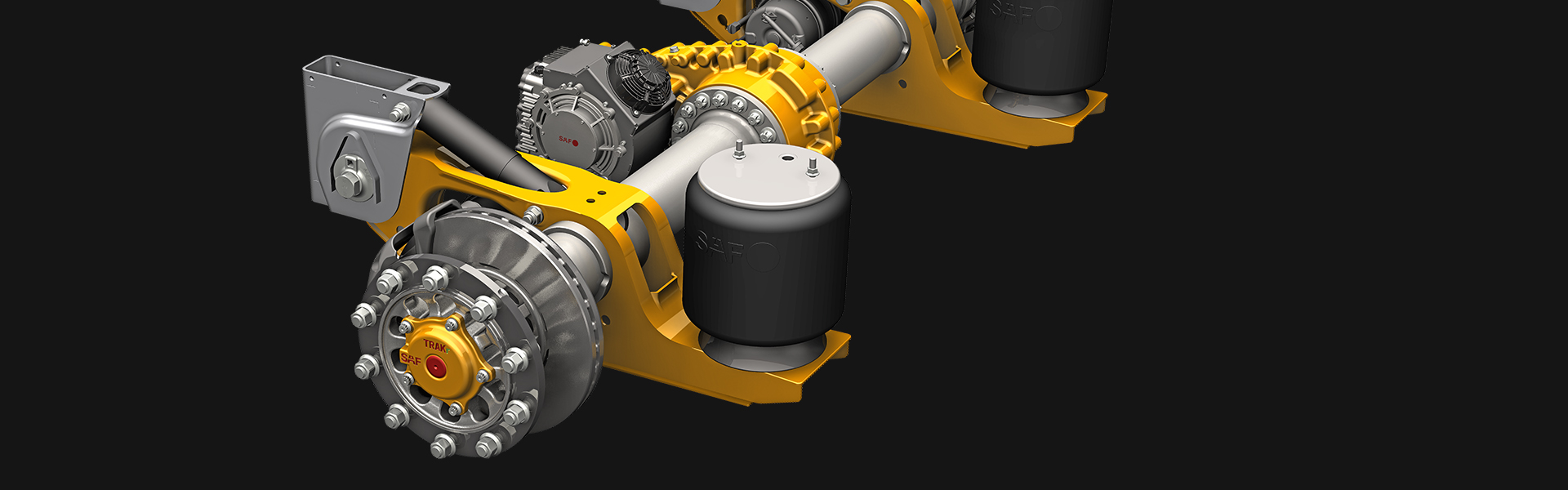

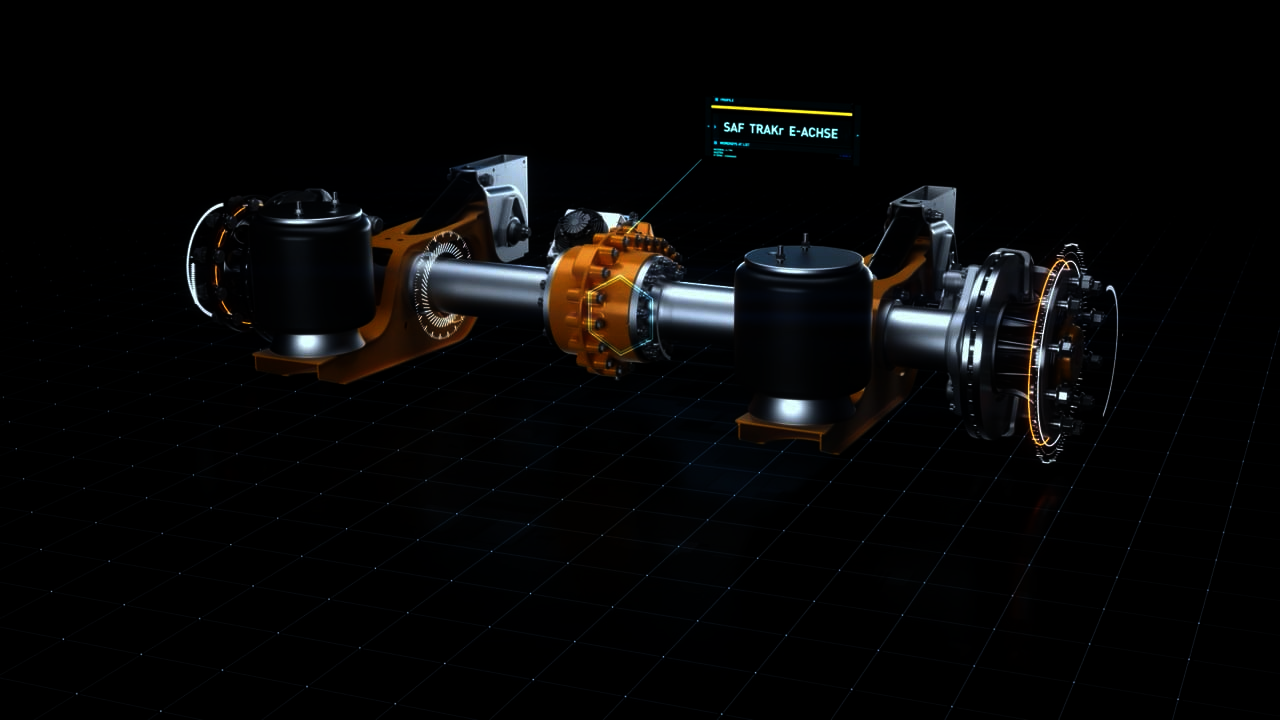

Technology of SAF TRAKr

The generator efficiently produces energy during driving and normal braking. Connected to the Trailer EBS CAN interface, the system automatically adapts its operation based on real time vehicle data.

The energy is temporarily stored in a Li ion battery using the electric CARRIER/ADDVOLT system, or it directly supplies auxiliary consumers in the trailer, such as refrigeration units, during operation. For maximum safety and performance, the generator automatically deactivates at low speeds, during emergency braking, or when driving stability events occur. The system is fully autonomous.

Benefits with SAF TRAKr

- Standardized system: Standard interfaces e.g. axles

- Significant weight reduction & increased payload

- Retrofitting possible

- Compliance to ECE reg. no. 13

- Independent from truck manufacturer

- Standard wear parts for simplified spare parts supply

- Simple maintenance: Maintenance of tires, wheel ends and brakes without dismantling the system

- Large ground clearance

- Wide range of variants

- Reduction of background noise while driving

- Significant weight reduction & increased payload

- More efficiency through reduced loading and idle times

- Driver-friendly and easy to operate

- Large ground clearance

Maximum Performance – Liquid or Air Cooled*

SAF TRAKr incorporates a future oriented e-machine concept with both liquid and air-cooled designs, covering a wide range of applications.

The liquid cooled permanent magnet machine (PSM) delivers up to 20 kW peak and 16 kW continuous power, making it ideal for power intensive applications with demanding thermal requirements.

The air cooled reluctance machine (RM) with innovative AEM HDRM technology offers the same performance with a robust, low maintenance design.

This ensures the right drive solution for every application: powerful, efficient, and uncompromisingly reliable.

*Air cooled variant currently under development.

Reliable even under Extreme Conditions

To ensure maximum safety and reliability, the SAF TRAKr axle was tested in northern Sweden at temperatures down to –40 °C under real extreme conditions including snow, ice, and slippery terrain. Successfully passing all tests.

These results demonstrate the robustness, reliability, and safety of the SAF TRAKr axle — even under the harshest operating conditions.

Sustainable Transport Starts Now with SAF TRAKr

Reaching the 1.5–2 °C climate target requires up to a 95% reduction in CO₂ emissions by 2030. Conventional diesel technology alone cannot meet future commercial vehicle requirements.

Customers are increasingly demanding greener transport solutions — and companies that act now will gain a clear competitive advantage.

SAF TRAKr in Action

The SAF TRAKr trailer axle has already undergone extensive testing and has accumulated several million kilometers of field experience. It is already in successful operation in real world fleets.

Thanks to the SAF TRAKr recuperation axle, Manuel Krauer, a truck driver at Switzerland's largest dairy Emmi, can park, load or unload anywhere without the noise of his diesel engine disturbing local residents.

Need More Information about SAF TRAKr?

Please visit our Download Center to access the product brochure and installation manual.