SAF-HOLLAND develops new products and upgrades to existing ranges not behind closed doors, but with a close eye on the requirements of the market. The best example: the millions of SAF INTRA air suspension systems that have been on the road for more than 20 years. From the outset, the suspension has been continuously optimised and expanded, turning the originally rigid unit into a complete family of axles, with self-steering and forced-steering axles or an electric generator as a drive.

Product development together with fleet customers

The dialogue with the fleet customers plays a key role for every innovation. Their wishes – such as durability, safety or reliability – are integrated into the development. Before the new products go into production, they are put through their paces on test beds and during test drives in everyday transport situations. SAF-HOLLAND develop products that support safety and continuously optimise these to ensure low operating and maintenance costs for our customers. During the practical tests, our new developments then have to prove that they can live up to our customers' expectations on the road as well.

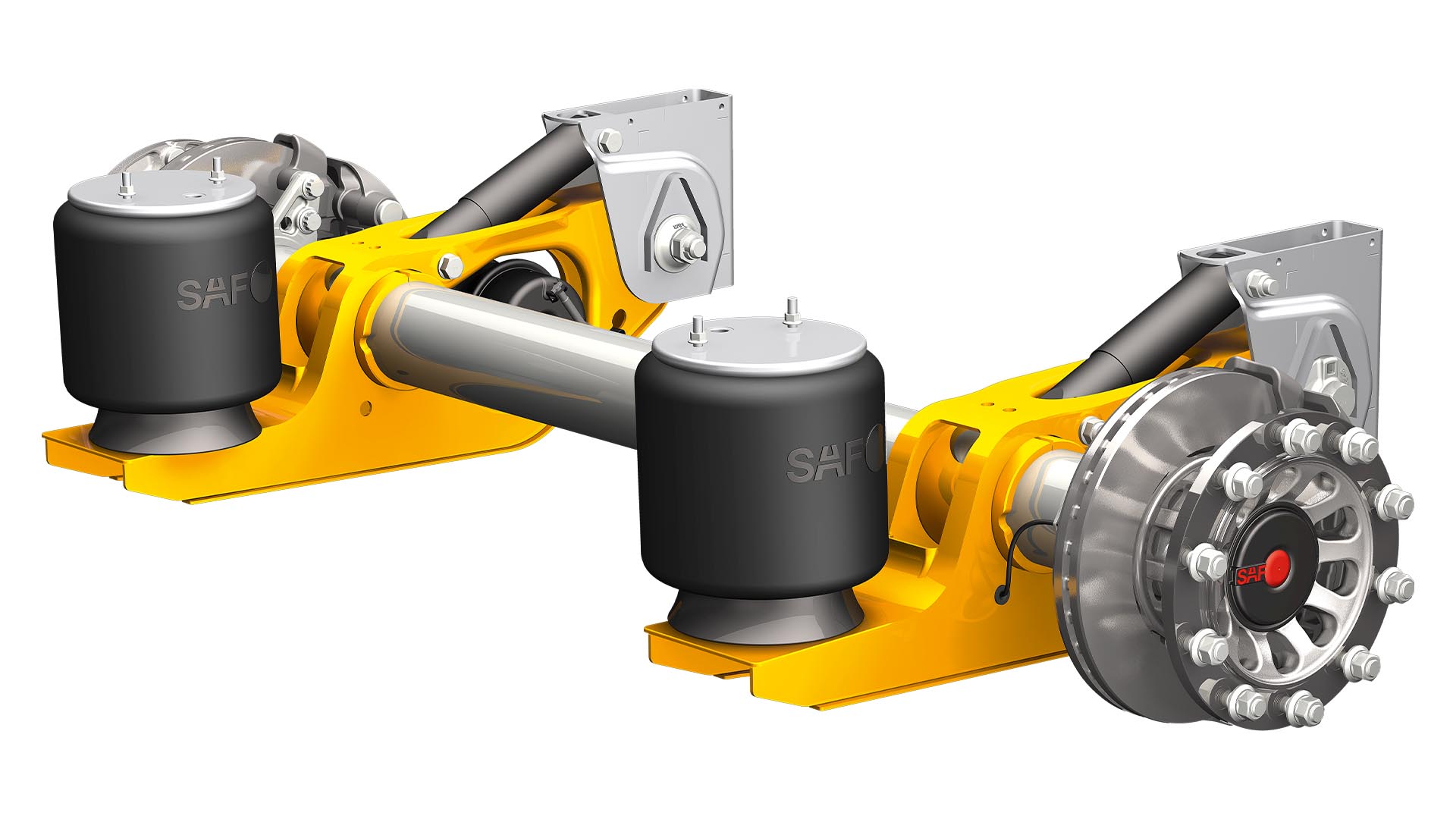

Continuous further developments pay off for the SAF INTRA family. On the test beds, the durability of the suspension has nearly doubled in the past 20 years, while the mileage is 1.8 times higher than for the original unit. At the same time, the weight has reduced significantly: Lightweight components, for example, mean that each SAF INTRA axle weighs about 70 kilogrammes less – on three axles, that saves 210 kilogrammes which the fleet operators can convert into a higher payload.

SAF INTRA: low wear – high safety

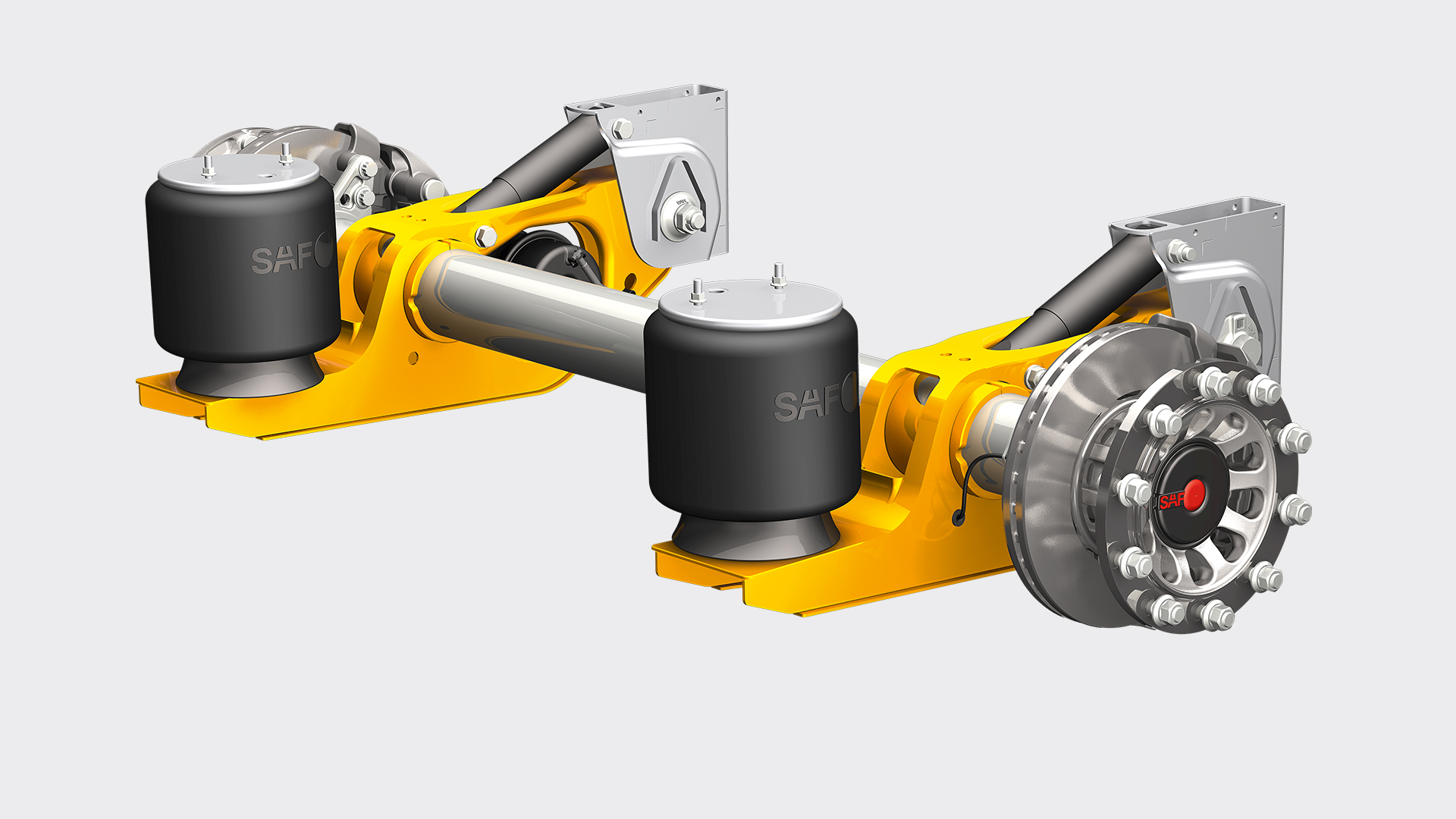

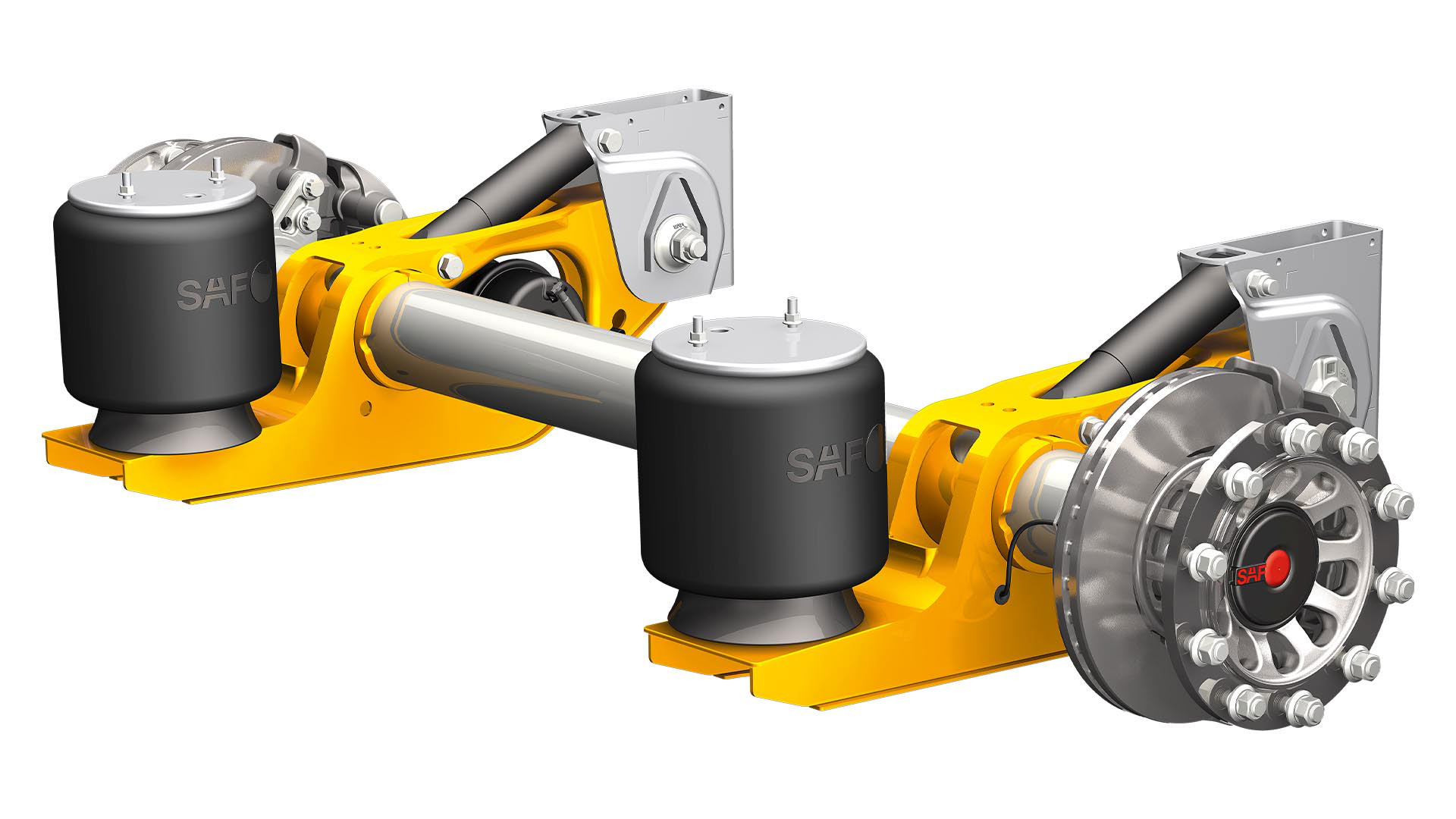

The axles from the SAF INTRA family follow a special design principle that ensures lower wear and more planning reliability. The functional suspension arm and the axle tube, for example, form a permanently connected, maintenance-free unit. The patented Safe-Guard design of the functional suspension arm additionally protects the brake cylinder against damage. The shock absorbers, which are positioned directly in the functional suspension arm, are also well secured.

With a robust and weight-saving design, the different axle variants feature sophisticated technical details and ensure that trailers travel safely on the road in all 9-ton applications. The latest developments in the SAF INTRA family are two electric axles and a specially coated axle for maximum corrosion protection:

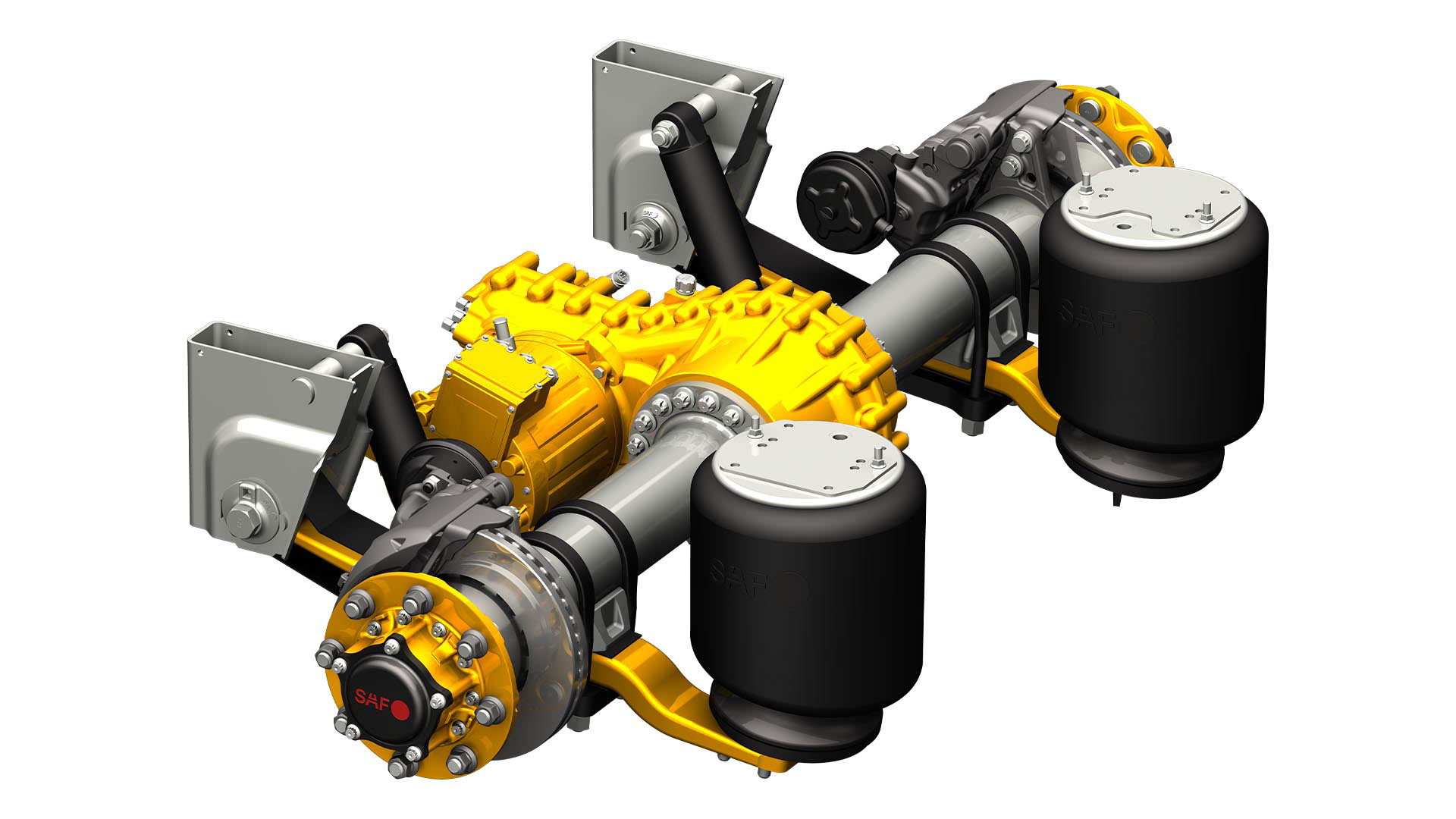

Electrified: SAF TRAKe and SAF TRAKr

SAF-HOLLAND launches two electric trailer axles so trucks and trailers can drive without emissions in the near future. The SAF TRAKr regenerative braking axle recovers motion energy which is converted into electricity. This is used to run auxiliary consuming units in the trailer, for example the cooling unit in refrigerated trucks. In addition, SAF TRAKe uses the stored energy to support the main drive of the tractor unit, for example in difficult road conditions.

SAF INTRADISC plus INTEGRAL with two-part brake disc

The two-part brake disc of the SAF INTRADISC plus INTEGRAL is a world's first: The special compound casting process prevents the formation of hot spots which can cause tensions and cracks in the material and ultimately a failure of the disc. This design therefore extends the service life of the brake discs and pads. Fleet operators benefit from planning reliability, higher efficiency and higher cost effectiveness.

10-year warranty for SAF INTRA PC PREMIUM COATED

The three-layer PREMIUM COATED process promises corrosion protection and great durability for the INTRA range. A high zinc content in the coating achieves high corrosion protection and preserves the value of the trailer in the long term. SAF-HOLLAND underlines this by offering a 10-year warranty against corrosion.