Find out here where our SAF-HOLLAND products are already being used and why our customers value SAF-HOLLAND as a supplier.

STORIES

SCM Fahrzeugbau: When something ordinary becomes extraordinary

In the Westphalian town of Borken, a small company has earned itself a special reputation: SCM Fahrzeugbau, founded by Hans Spiller, stands for customized vehicle solutions that cannot be found in catalogs. With just four employees, the company builds what others refuse to: individual superstructures, special trailers, and conversions—precisely, practically, and quickly. “Short service channels, fast response times” is not just a cliché here, but part of everyday life.

A request turns into a customized overall concept

The inspiration came from GARTS GaLaBau GmbH & CO. KG in Kirchlinteln, Lower Saxony. The renowned gardening and landscaping company was looking for a compact transport solution for larger and heavier machines. Previously, it had used a so-called mini semi-trailer truck—a transporter-based converted towing vehicle that could be driven with a Class BE driver's license, but was fragile and technically limited.

With these very specific requirements, the customer came across SCM. In an intensive coordination process, a completely new concept was developed together – tailored to his fleet, his machines, and the legal requirements. Thus, with the support of SAF-HOLLAND, an initial inquiry turned into a technically sophisticated, practice-oriented semi-trailer.

Why a semi-trailer truck—and not a center-axle trailer?

Center-axle trailers are considered standard in gardening and landscaping—compact, maneuverable, and with a high payload capacity. So why a semi-trailer?

- The reasons are in the details:

Loading space: The machines to be transported were getting bigger—the semi-trailer offered a continuous, longer loading area - Load distribution: A semi-trailer allows a fifth-wheel load of up to 5 tons – this significantly increases the payload potential while maintaining the same total weight

- Flexibility in the vehicle fleet: The vehicle was designed so that it could continue to pull conventional trailers – “a jack of all trades,” according to Spiller

- Driver's license benefit: Under certain conditions, the entire combination can be driven with the old Class 3 driver's license, among others – an underestimated but practical advantage for many companies

Engineering in a nutshell – with SAF-HOLLAND as your partner

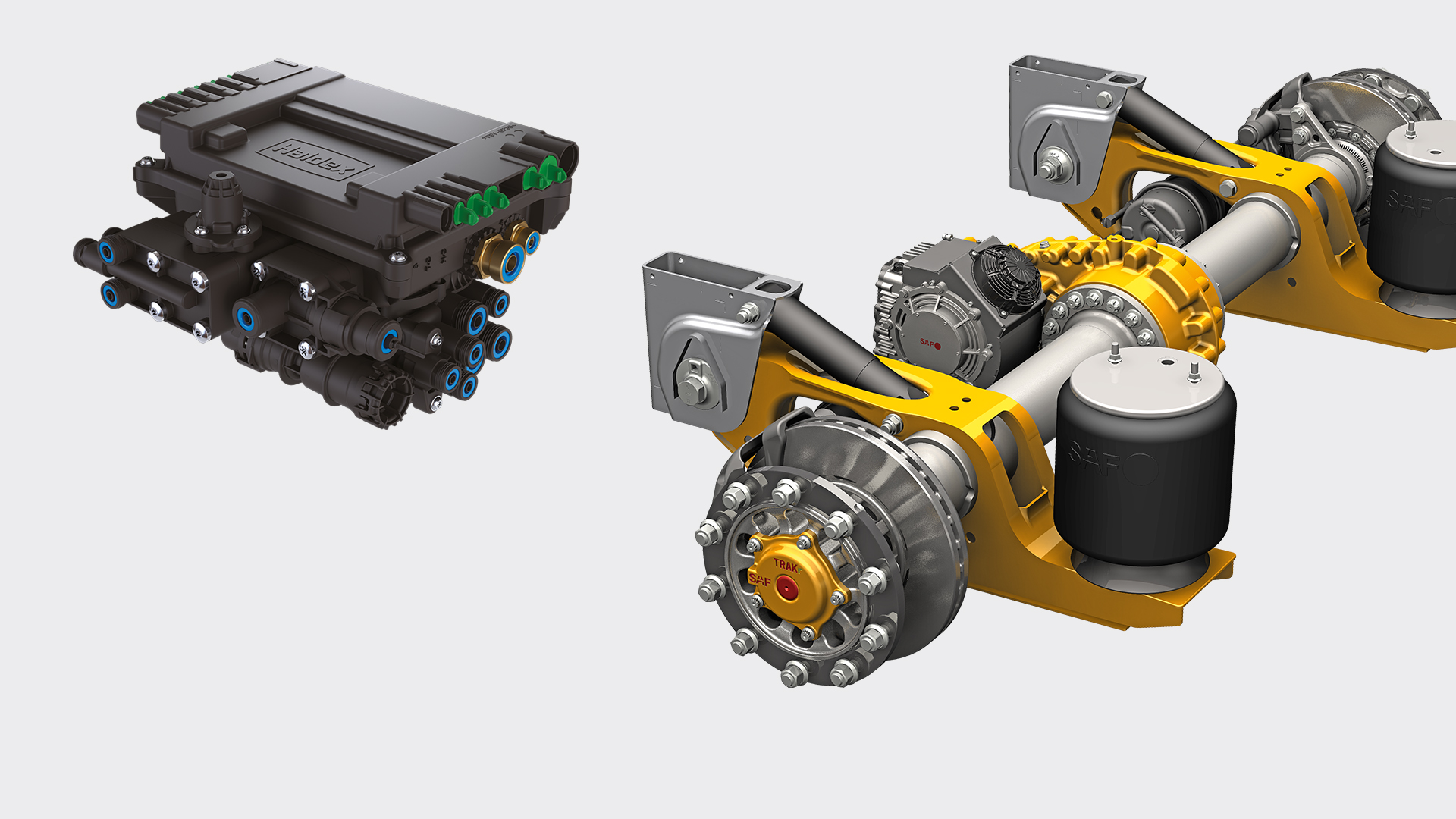

The tractor unit is based on a Mercedes Atego, which is no longer available as a semi-trailer tractor from the factory. So SCM converted the series chassis itself: frame shortening, mounting plate, fifth wheel, compressed air and electrical system – all from a single source. SAF-HOLLAND was brought on board as a partner for the coupling, kingpin, landing gear, and axle.

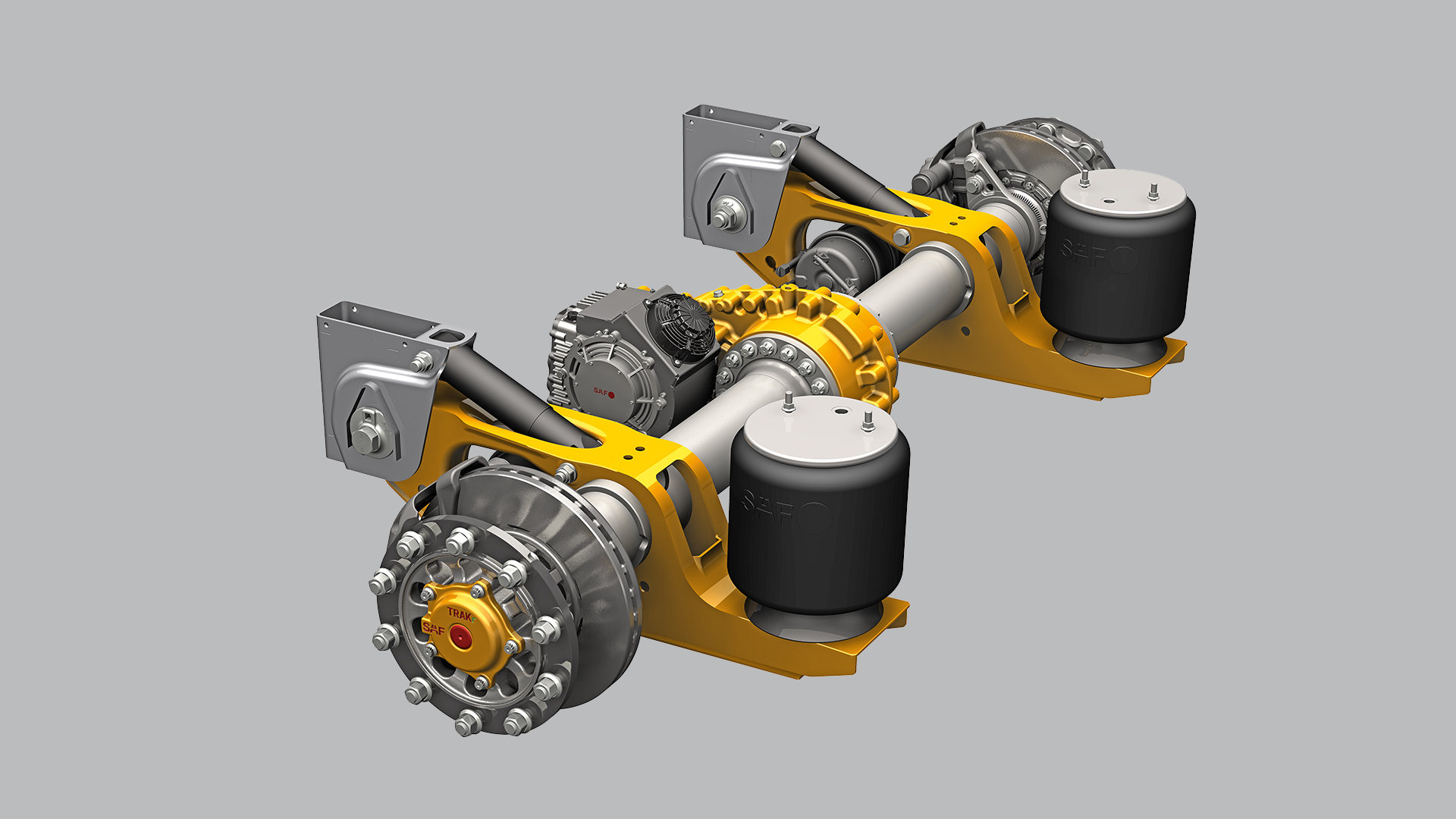

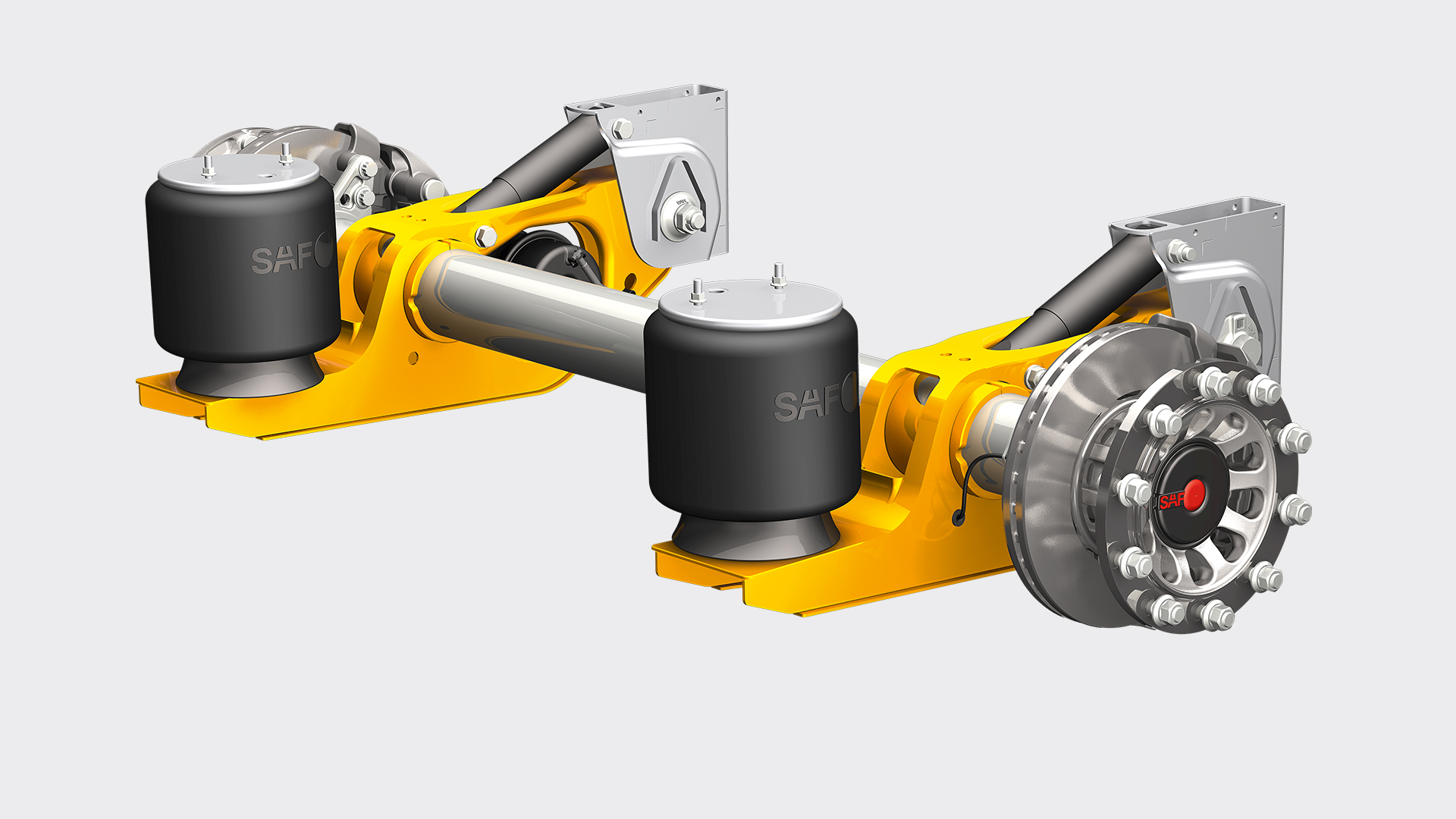

“We always try to use standard products – simply to ensure maintenance can be carried out in independent workshops,” explains Hans Spiller. Together with SAF-HOLLAND, a customized low-loader axle with air suspension was specified that was precisely tailored to the requirements – even though the desired dimensions were not listed in the catalog. “Nevertheless, SAF-HOLLAND was able to develop a solution from its modular system that will ensure that all spare parts remain available in the future.”

Single-axle semi-trailer with brains – for narrow construction sites and tall machines

One of the customer's key requirements was the lowest possible loading height, resulting in a flat ramp angle for sensitive attachments on the construction machines. The challenge: the axle load had to be maintained despite the lowered height. A good compromise was achieved by combining a 9-ton axle with optimal tire dimensions. Additional ramp adjustments ensured the necessary flat position when driving up.

Reversing maneuvers are also improved. The single-axle design ensures maximum maneuverability, which is a clear advantage in residential areas or narrow construction site access roads.

Individually tailored – down to the last detail

Whether lashing points in the perforated floor frame profile, special ramp angles, or positioning of the trailer coupling – the vehicle was completely tailored to the customer's specifications.

Partnership on equal terms “Every axle counts”

He has particularly fond memories of working with SAF-HOLLAND: “I consider it remarkable that even small vehicle manufacturers are treated as equals at SAF-HOLLAND. Our contact, Mr. Weber, was always available, contributed ideas, and—when necessary—suggested alternatives. It was a thoroughly positive experience. It doesn't matter whether you come up with a special solution or order 1,000 axles a year – you are really considered seriously.“

Result: A vehicle that sets an example

The project not only impressed GARTS GaLaBau – even the Mercedes-Benz branch in Bremen was impressed. Spiller believes that the solution could also be of interest to other companies in the future:

”The concept certainly has potential. Of course, the initial investment is higher than for a series-production product – but for some customers, this is exactly the solution that makes their everyday work much easier."

Conclusion: The SCM Fahrzeugbau project shows how technical expertise, solution-oriented thinking, and partnership-based cooperation can result in a special solution with real added value – economically, legally, and in terms of its practical suitability for the tough everyday conditions on construction sites.

WIESE Fahrzeugbau manufactures special trucks with hook lift trailers and VSE Advanced Steering electrohydraulic steering systems.

The Challenge:

Transporting wood chips from the forest places high demands on the vehicle. The load is produced directly in the forest and must be transported efficiently to an interim storage facility for drying. Two factors are crucial here: maximum load volume and high maneuverability to enable optimum operation in the forest despite confined space and rough terrain. In addition, roll-off tippers should be used for transport to enable flexible and economical logistics.

The Solution:

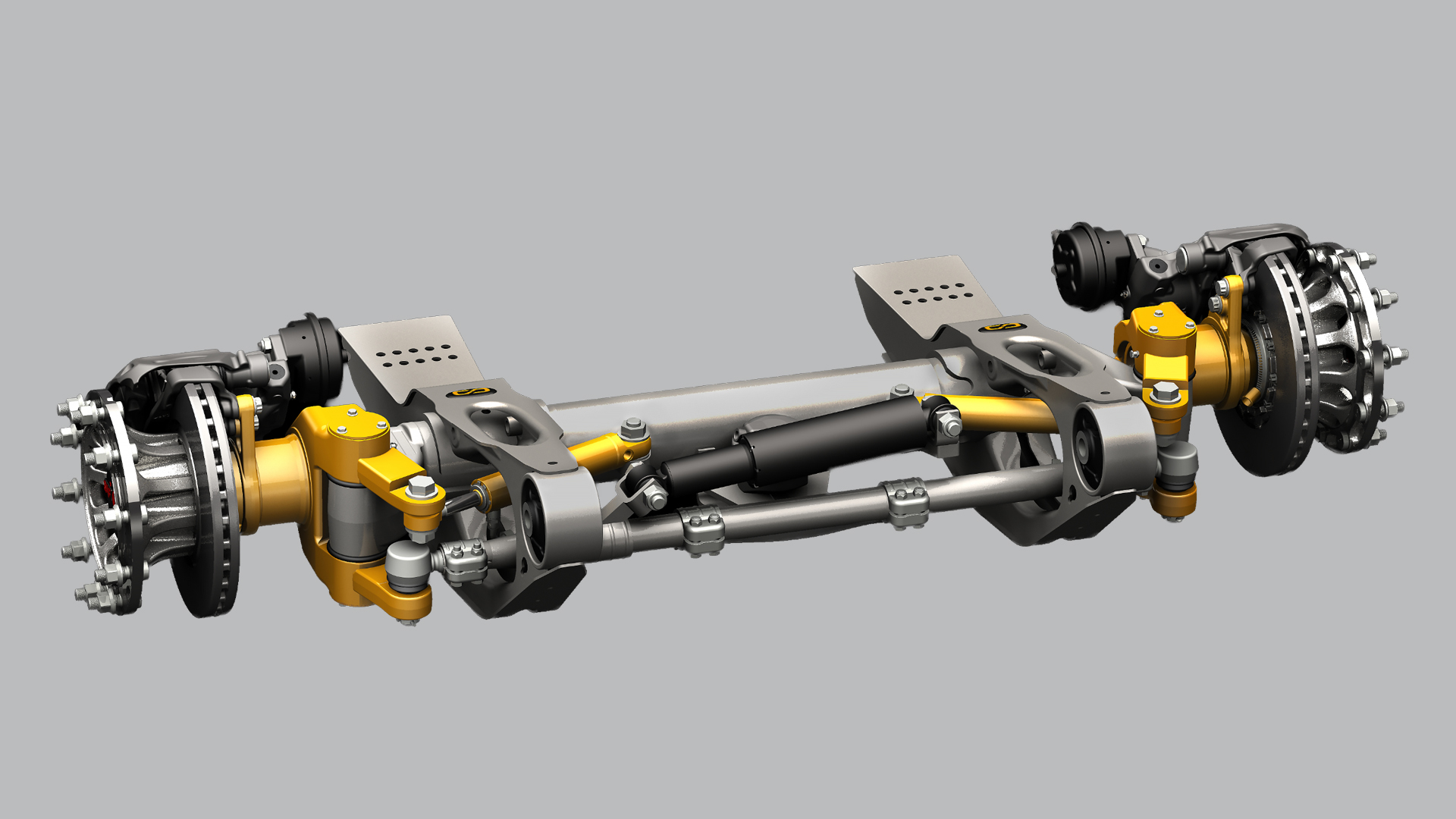

Following intensive discussions between WIESE Fahrzeugbau and SAF-HOLLAND, a unique vehicle concept was developed: a 2-axle roll-off tipper with VSE Advanced Steering electro-hydraulic steering system and a specially designed 50 m³ roll-off container. The vehicle has three axles on the truck and two forced-steering axles on the trailer – an extremely rare configuration. While conventional semi-trailers usually have three rigid axles, WIESE specifically uses steered axles to maximize maneuverability and agility.

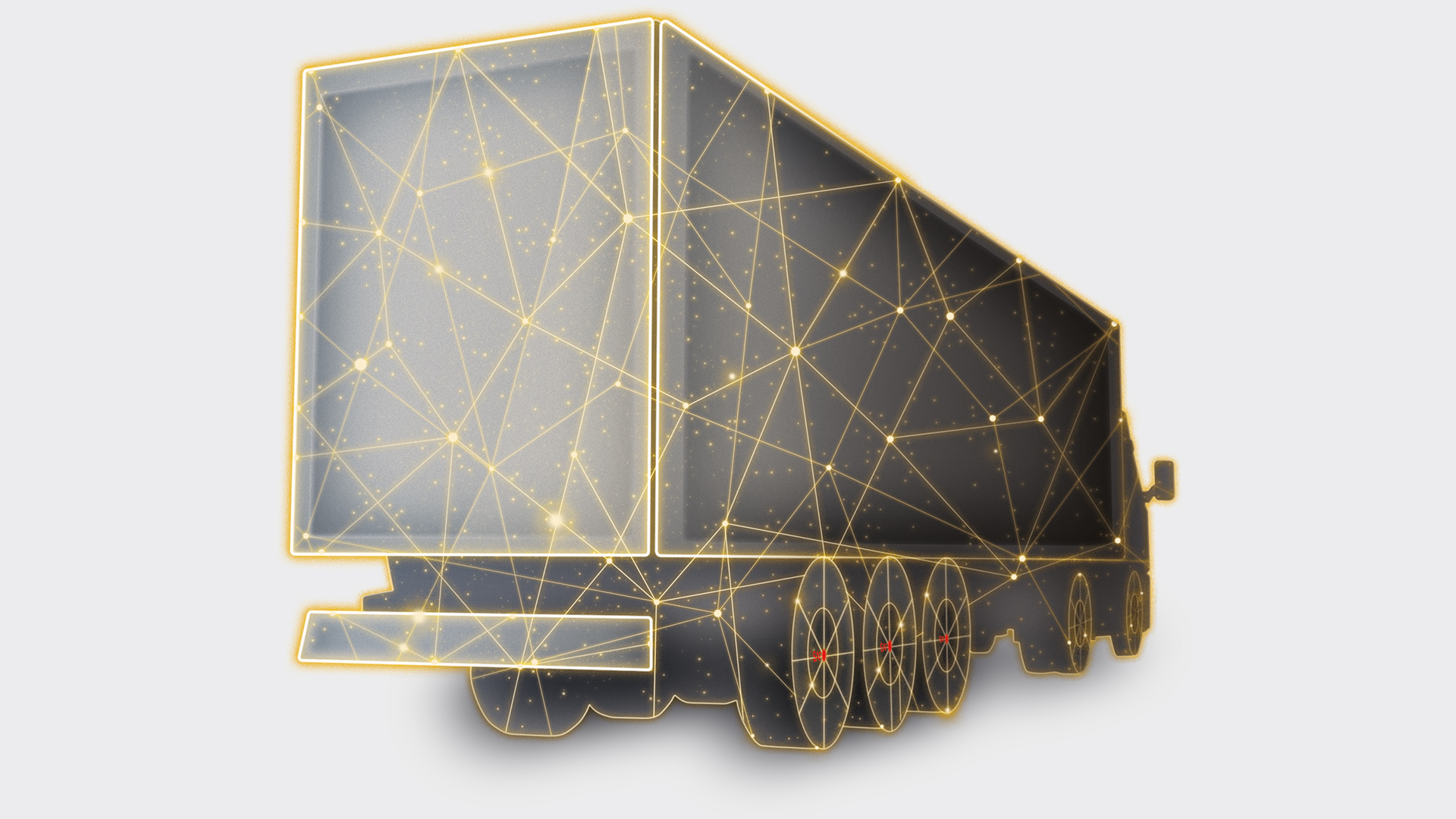

To meet these requirements, VSE Advanced Steering was chosen. The electrohydraulic steering system offers significantly more than classic mechanical solutions: it continuously analyzes the vehicle's speed, steering angle, and direction of movement and controls the steering movements of the trailer axles in real time. The key feature is that the system operates completely independently – without any mechanical connection to the towing vehicle – and can be customized to suit almost any type of vehicle.

The Special Feature:

Unlike trailing steering systems (based on the “shopping cart principle”), this semi-trailer uses two genuine forced steering axles – a technically sophisticated solution, especially in a 2-axle design. The steering arms are arranged parallel to the axle body, enabling precise control, even when reversing. This design clearly sets it apart from other systems, where such implementation would not be possible in a 2-axle semi-trailer.

This VSE steering system offers decisive advantages, especially in demanding forestry applications:

- Enormous maneuverability in confined spaces – ideal for hard-to-reach forest paths and cramped storage areas

- Precise maneuvering (especially when reversing) even under load, thanks to centimeter-precise electronic control via steering angle sensors

- Less tire wear thanks to precisely calculated steering angles, which is particularly valuable when driving on loose ground

- Full flexibility in design, as no mechanical connection to the truck's steering is necessary

- Reduced fuel consumption and higher efficiency thanks to lower rolling resistance when cornering

The built-in hook lift also ensures maximum flexibility during loading and unloading. It enables containers to be set down and picked up quickly and safely – even on uneven ground. This is an invaluable advantage, especially in remote forest areas: the driver can set down the loaded container, pick up an empty one immediately, and thus minimize downtime. In addition, the system offers the option of using different container sizes and types, which significantly increases the vehicle's versatility.

Technical Implementation:

Close communication between WIESE Fahrzeugbau and SAF-HOLLAND was essential from the initial idea to the final design. WIESE had a clear idea of the dimensions, axle loads, and brake systems. The SAF-HOLLAND sales team then searched for a suitable axle configuration—such solutions are often tailor-made new developments.

The Process in Detail:

After selecting the appropriate axle assemblies, drawings and 3D models were created to optimize the design. WIESE then received the technical documentation and planned the integration of the components into the vehicle frame with VDL hook lift. Production started about two weeks before delivery of the axle assemblies. After assembly and final testing, the special vehicle was shipped to the customer in Austria, where it has been impressing in daily use under real-life conditions.

The Result:

The vehicle sets new standards for wood chip transport:

- Maximum maneuverability thanks to the VSE Advanced Steering electrohydraulic steering system

- Maximum efficiency thanks to a large loading volume and a flexible roll-off tipper

- All-terrain capability for reliable operation even in difficult terrain

- And an extremely satisfied customer

Johannes Suntinger, who ordered the vehicle for his timber transport company in Austria and also drives it himself, is enthusiastic after approximately two months and “2,000 km in the forest”: "Many roads here are extremely narrow, and the tight corners are often a real problem. This makes it all the more important that the trailer follows the steering movement precisely. And that works perfectly with the two steering axles. With the steering, we can get anywhere cleanly, even when space is really tight."

The many years of cooperation between WIESE Fahrzeugbau and SAF-HOLLAND have once again proven their worth. Thanks to close technical exchange and precise coordination, complex requirements were translated into a well thought-out, highly functional solution. WIESE particularly emphasized the high-quality technical support and fast communication channels – further proof of the successful partnership.

With this unique vehicle solution, SAF-HOLLAND underscores its expertise as a reliable partner for innovative and high-performance axle and steering systems in commercial vehicle construction.

Fahrzeugbau Strehlow relies on VSE Advanced Steering for innovative semi-trailer

How do you get a 450-tonne crane jib safely through Berlin's construction site traffic without a permit? Fahrzeugbau Strehlow and SAF-HOLLAND have the answer: with an ultra-light special trailer equipped with two electro-hydraulic steering axles.

Narrow construction site access roads, inner-city traffic and heavy equipment: for Berlin-based crane rental company Mobi-Hub, it was clear that no standard solution would be suitable for transporting the boom of a 450-tonne mobile crane. The challenge: the semi-trailer had to be light enough to remain below 41.8 tonnes total weight – the limit at which a vehicle is classified as heavy goods transport and requires a permit. At the same time, maximum manoeuvrability was required. Fahrzeugbau Strehlow from Oranienburg took on this task – with the support of the VSE Advanced Steering system.

For over 30 years, Mobi-Hub has relied on the expertise of Fahrzeugbau Strehlow for particularly demanding semi-trailers. As a long-standing partner for customised vehicle solutions, the company from the Oberhavel district in Brandenburg is known for its unconventional and tailor-made designs. Once again, Strehlow delivered a well thought-out solution: a two-axle semi-trailer with electro-hydraulic steering, which is precisely tailored to the high demands of heavy transport thanks to its lightweight construction and clever weight distribution.

The highlight: The crane boom itself is an integral part of the stability during transport. The semi-trailer is designed so that the boom rests on two defined points and takes on load-bearing functions. This has reduced the weight of the semi-trailer to around 4.5 tonnes – well below the original target. Goal achieved: including the tractor unit, the transport remains below the critical 41.8-tonne mark and will no longer require a special permit in future.

Mr Brecht, senior truck dispatcher at Mobi-Hub, is thrilled:

‘The entire truck can simply drive off like a normal truck – turn the key, step on the gas and go.’

Two steering axles with VSE Advanced Steering provide the necessary manoeuvrability. These are electronically controlled and allow precise steering – even at low speeds and in confined spaces. Thanks to the practical remote control, the steering can also be taken over by a second person if necessary – for example, by the crane operator while the driver concentrates on manoeuvring.

Mike Brecht sums it up:

‘The VSE axles are ideal for our requirements. They are extremely easy to operate and offer outstanding manoeuvrability. The trailer can be driven without any major adjustments, which saves time and makes us more flexible in our work. All of our drivers feel comfortable with the steering axles after just a short time.’

By eliminating time-consuming approval procedures, Mobi-Hub can now carry out its transports faster, more cost-effectively and with greater flexibility. Especially in the greater Berlin area, where narrow access roads and inner-city construction sites are commonplace, the new trailer provides a clear operational advantage.

With VSE Advanced Steering technology and the innovative design from Fahrzeugbau Strehlow, a solution has been created that perfectly combines functionality, efficiency and practicality. The project once again demonstrates how close cooperation between the customer, vehicle manufacturer and supplier can result in solutions that are not only technically impressive, but also economical and practical for everyday use.

The trailer has been in successful use since April 2025, and Mobi-Hub is already considering making the originally customised semi-trailer available for smaller crane jibs in the future with minor modifications. A compelling example of active partnership and technical intelligence – made by SAF-HOLLAND.

TECMA develops customized heavy-duty axle

Extreme loads, rough terrain and the highest safety requirements - the operator needed a special two-axle heavy-duty trailer for the energy supply in open-cast mining and presented Gloria Fahrzeugbau Bierewirtz GmbH & Co KG with a tricky task.The trailer was to be used to reliably transport and lay belt coils weighing 50 tons for the open-cast mining equipment. As a specialist for customized heavy-duty axles, TECMA found a clever solution that could reliably withstand the high loads and Gloria was able to deliver a perfect solution for its customer.

In the rugged environment of open-cast mining, one thing counts above all: robust, reliable technology. Gloria Fahrzeugbau, a traditional company based in Grevenbroich, specializes in the development and construction of tailor-made truck bodies and special trailers. With decades of experience in the construction of sophisticated vehicle solutions, the company was the ideal partner for the development of a heavy-duty trailer. This was to transport heavy belt coils for the numerous conveyor belts used in open-cast mining.

The requirements were enormous: a total load capacity of 85 tons distributed over just 2 axles, high braking power, ground clearance for rough terrain and extreme load capacity. When designing the trailer, it quickly became clear that the axles and brakes in particular would be under extreme strain. Not an easy task - and certainly not one that could be fulfilled with standard components.

In the search for a suitable partner, the choice quickly fell on TECMA. The SAF-HOLLAND brand has specialized in the customer-specific design and manufacture of axles and suspensions for over 30 years and is renowned for its heavy-duty solutions.

Due to this unique position and the long-standing cooperation with SAF-HOLLAND, TECMA was commissioned to develop an appropriate axle and brake solution for the specific requirements of Gloria Fahrzeugbau. The cooperation took place in close coordination between all parties involved.

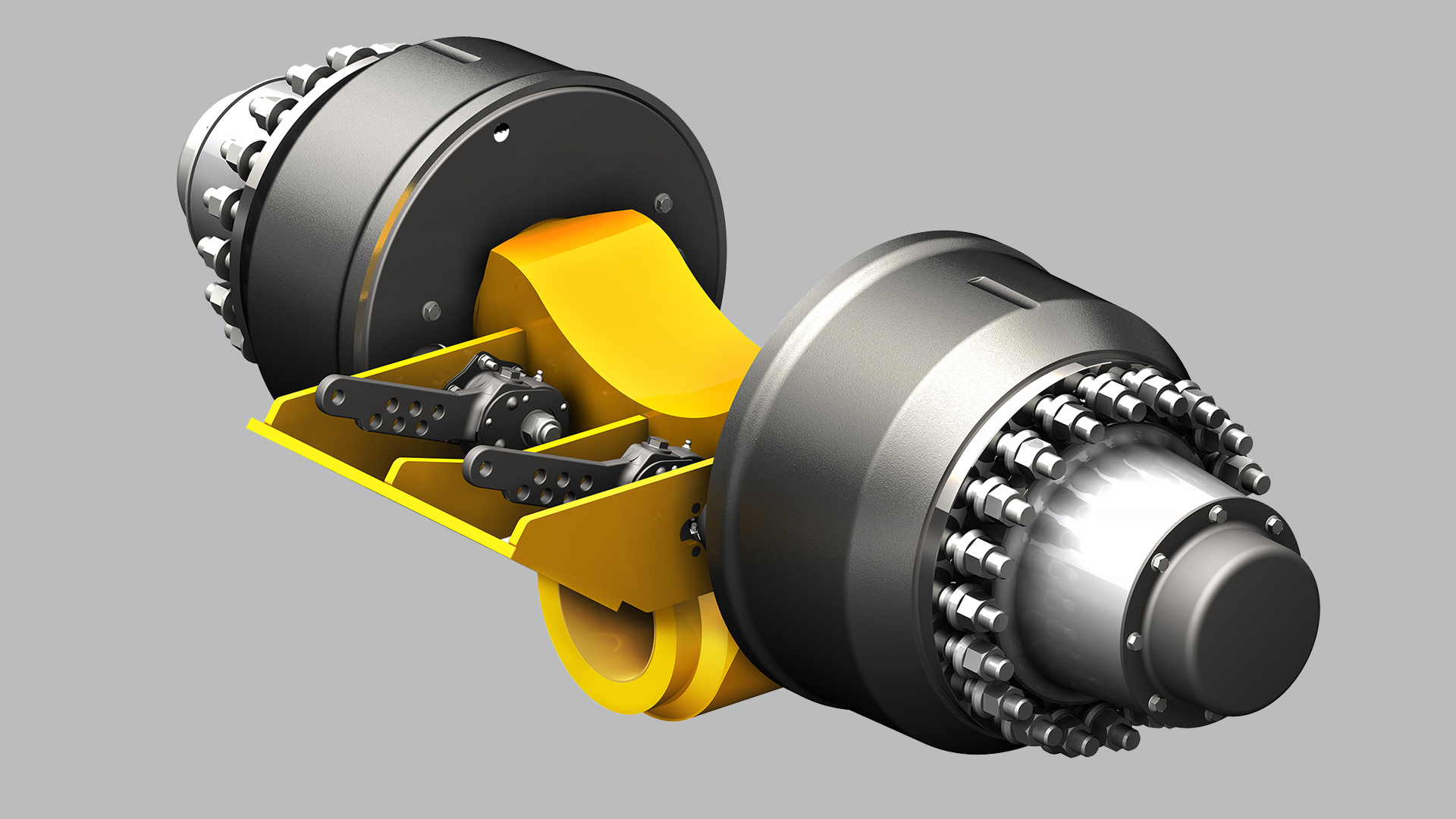

FEM calculations (finite element method) were used to determine the optimum axle design. The result was a heavy-duty axle that easily meets the specifications, such as the exceptionally large track width of 2,630 mm and the enormous load capacity of 42.5 tons per axle. The calculations took into account all the important factors such as load capacity, stability and safety in order to withstand the extreme conditions in open-cast mining.

The brake design proved to be more difficult. While the braking energy required was relatively low due to the low maximum driving speed of 8 km/h, the combination of high axle loads and large wheels required a very high braking torque. TECMA found a surprisingly clever solution to this requirement.

After drum brakes were unable to achieve acceptable braking values, the decision was made to use disc brakes. And with the defined braking system, an extremely simple but effective solution was found: two brake callipers per wheel end. This technical “trick” of doubling the brake callipers also doubled the braking torque.

Fortunately, the customer was also enthusiastic about the solution and gave the go-ahead for the implementation of the concept. Once development was complete, the entire construction, known internally as the “Big Duck” due to its size and color, was put through its paces together with the TÜV - with outstanding braking values.

Felix Bierewirtz, Managing Director of Gloria Fahrzeugbau, is visibly satisfied: “The entire collaboration with TECMA went very smoothly. The required specifications were met in full, and all technical and scheduling agreements were reliably adhered to. Special applications are always based to a certain extent on trust between the partners involved. This trust existed here from the very beginning and was confirmed in every phase of the project.”

With this successful project, TECMA and SAF-HOLLAND show that innovative technology and partnership-based cooperation lead to outstanding results, even under the toughest conditions. The trailer has now been used in open-cast mining for over a year without complaint and has proven to be a reliable, robust solution.