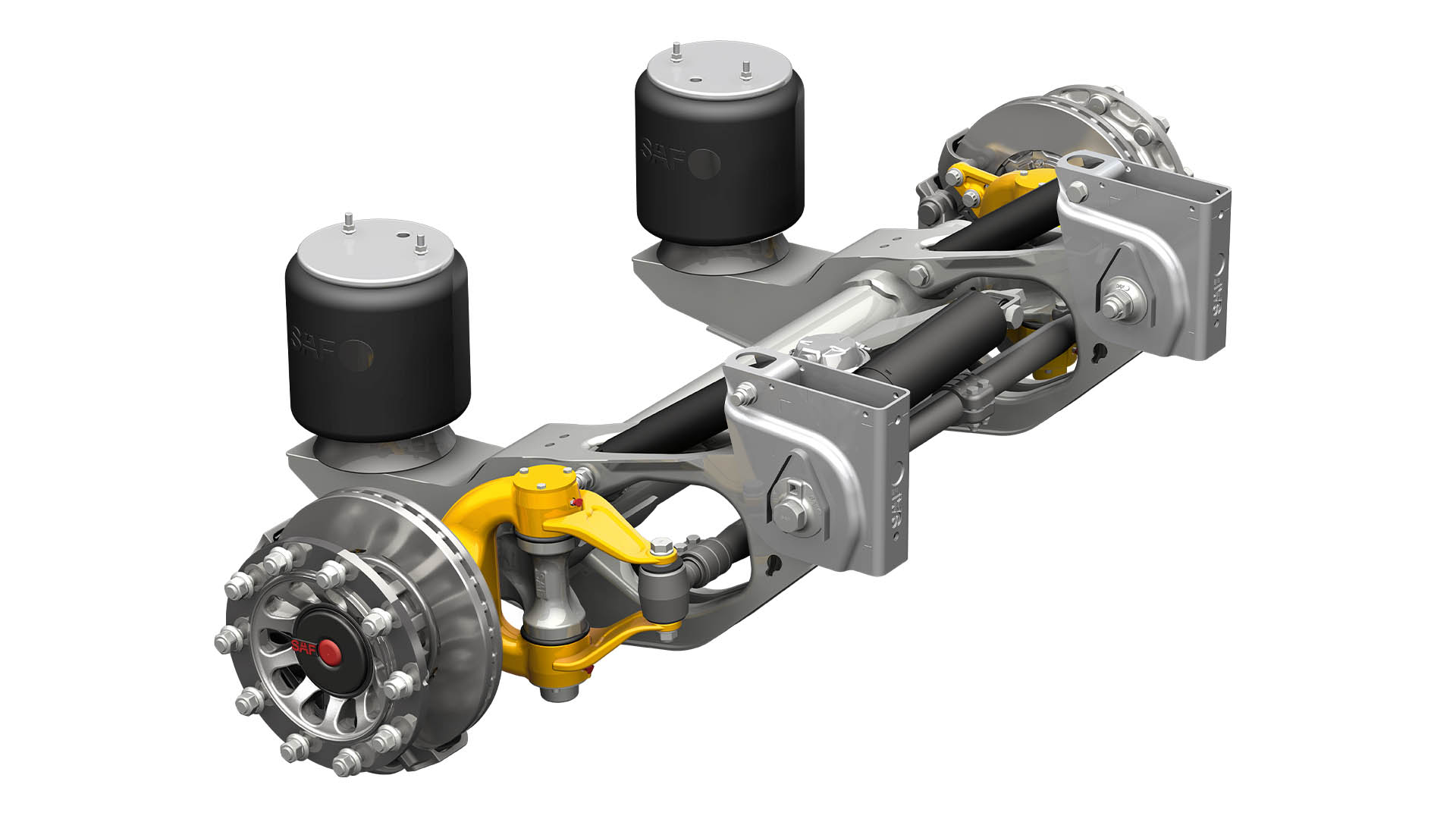

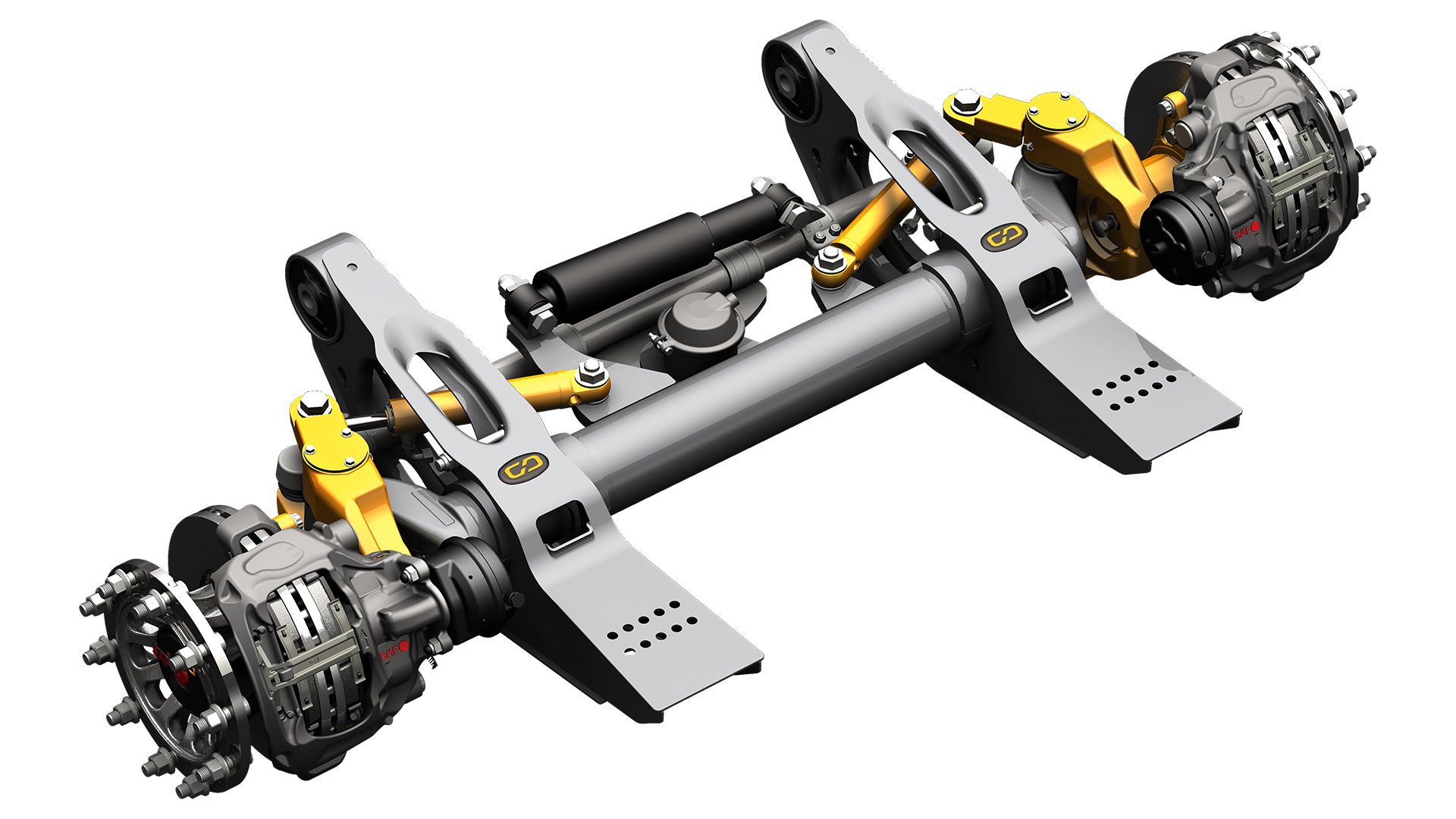

The SAF INTEGRAL technology is unique worldwide and protects the material and extends the service life of the axle. For the economical and highly efficient INTEGRAL brake disc, SAF-HOLLAND uses a two-stage casting process that combines two high-quality materials in one component.

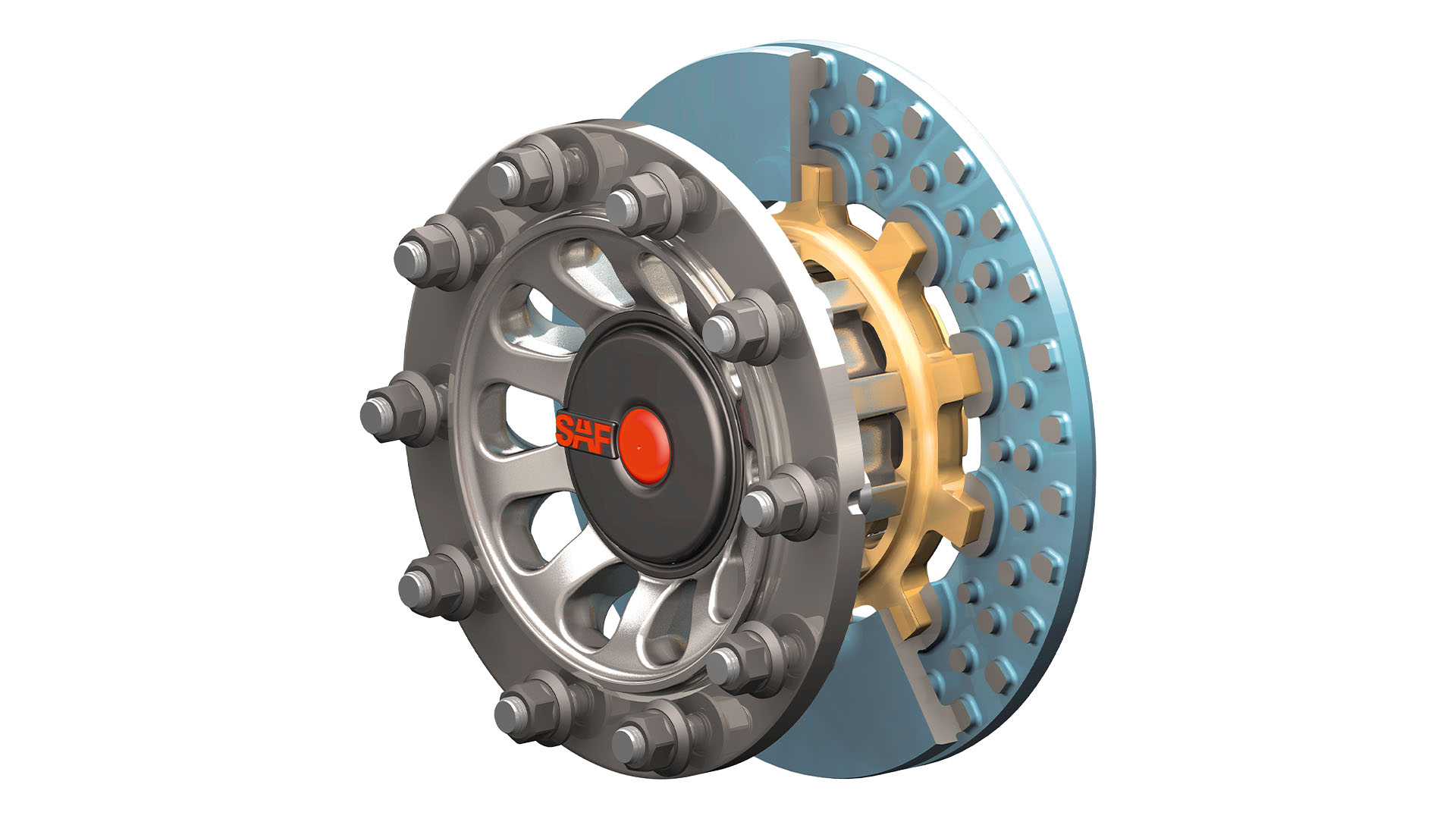

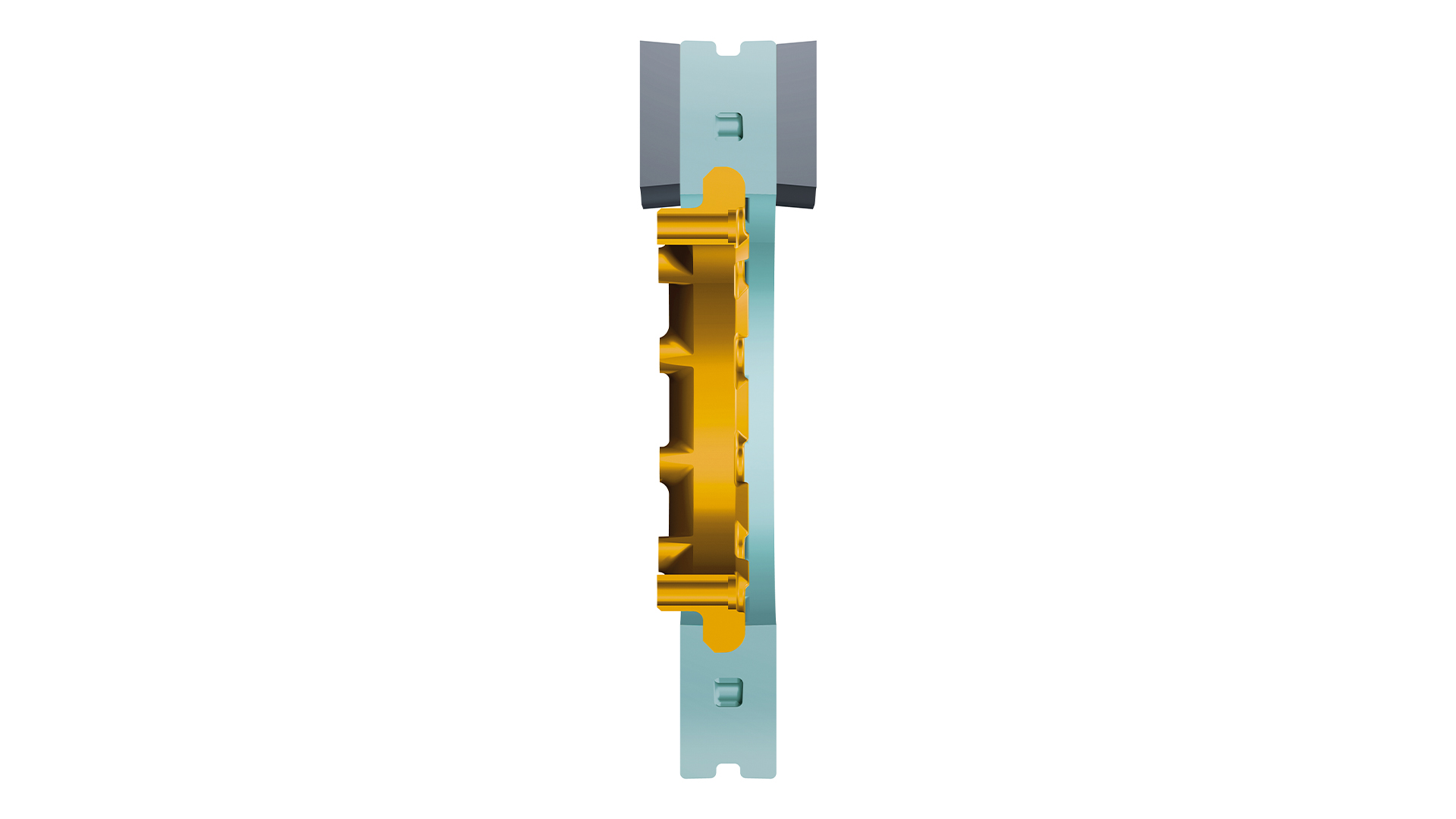

The special composite casting process of the INTEGRAL disc prevents damaging cracks. In this design principle, the disc is cast onto a toothed adapter ring and bolted to the wheel hub. The cast iron friction ring sits absolutely backlash-free on the cast steel adapter ring.

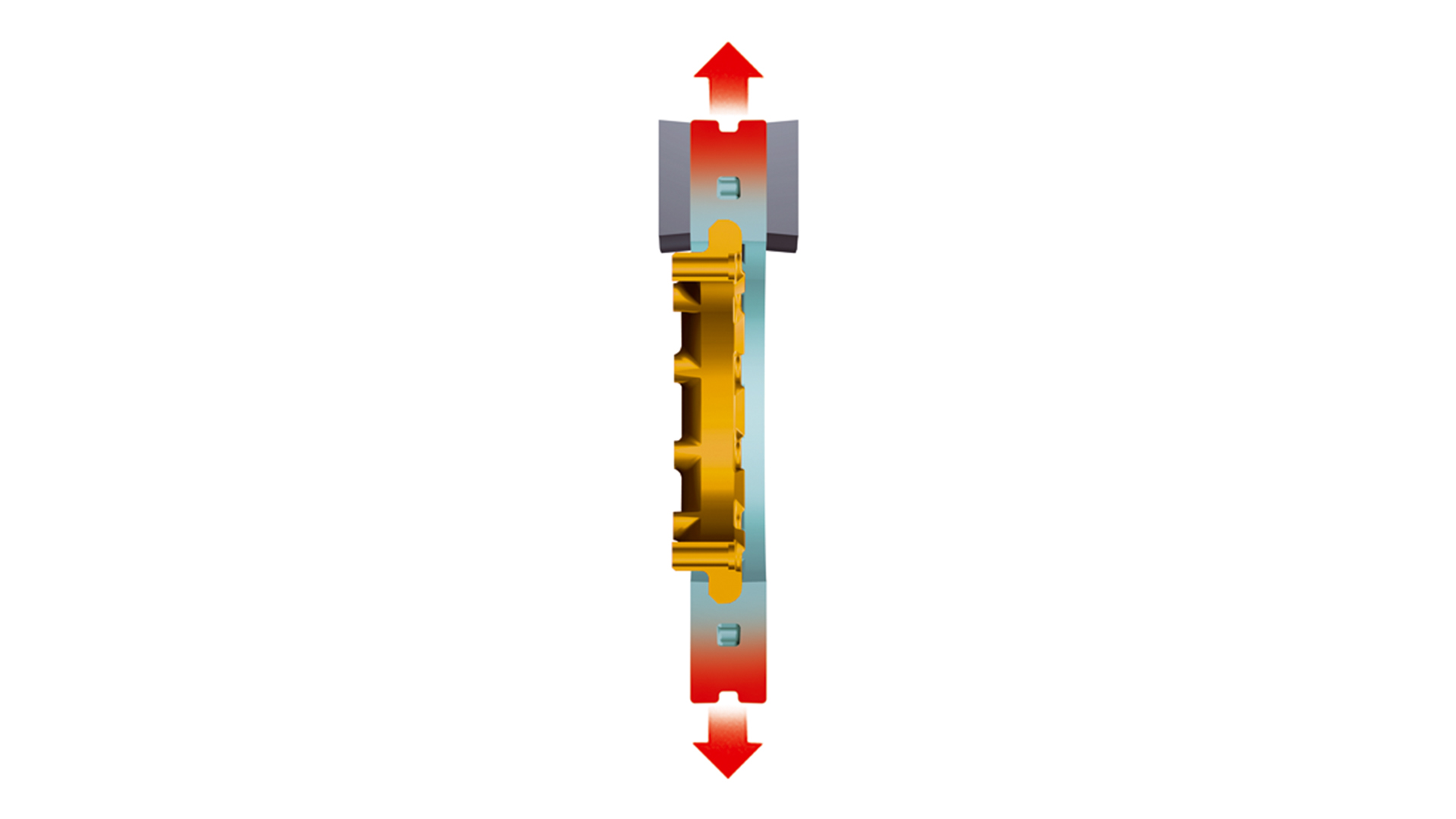

If heat is now introduced during braking, the friction ring expands only radially, thus preventing uneven thermal stresses. On cooling, the disc also contracts again radially. This avoids the formation of hot spots, which in conventional brake discs can lead to stresses and cracks in the material and thus to complete failure.

Since the braking surfaces remain perfectly flat in any operating condition, the pads last significantly longer when the INTEGRAL disc is used. This technology thus has a positive effect on the service life of the brake disc and the brake pads.

-

No stress cracks due to uneven heat input

-

Always flat braking surfaces increase the service life of the brake pads

-

Due to ventilated adapter surfaces only little heat input into the wheel hub

-

Optimum internal ventilation of the brake disc due to conical air channels